Erzurum Electric Motor Sales

Contact: +90 (542) 666 11 11

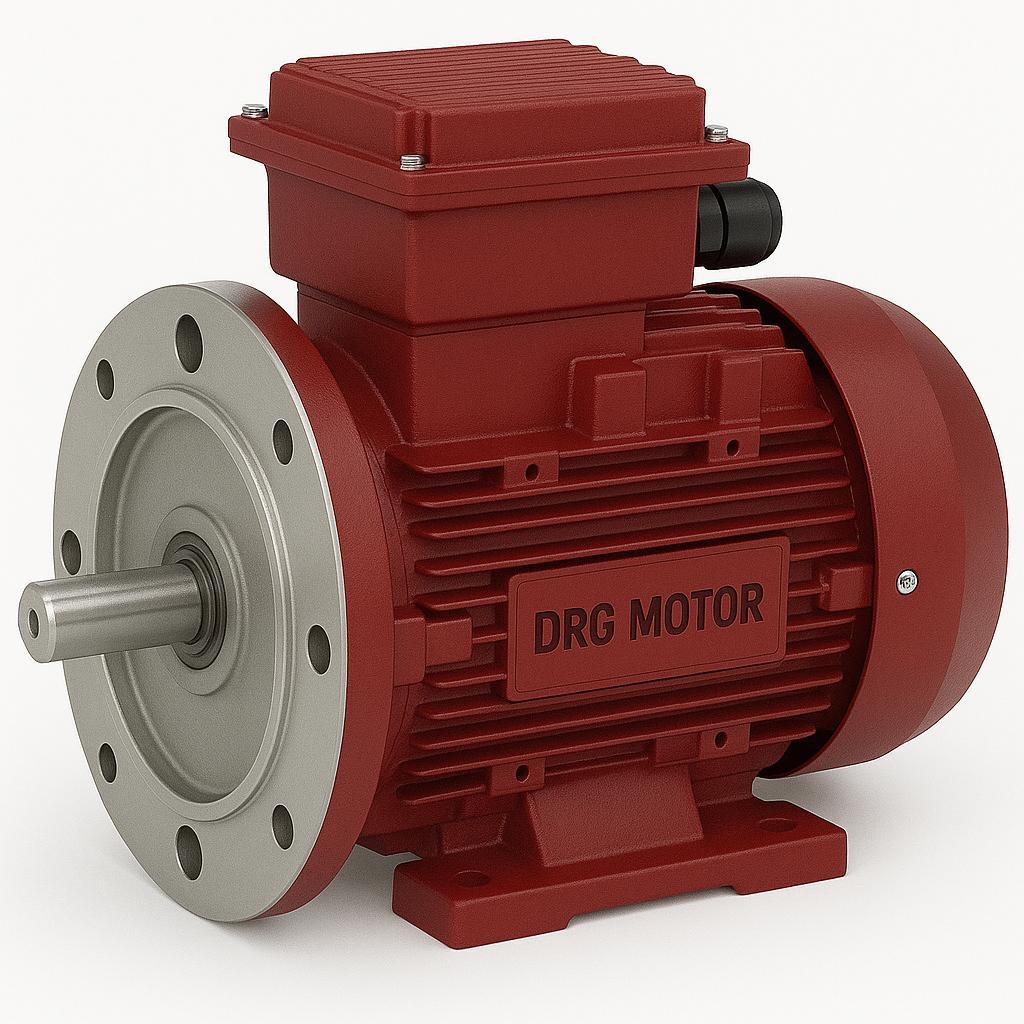

Erzurum is one of the most strategically located industrial centers in Eastern Anatolia, with a growing need for reliable, energy-efficient, and durable electric motors. Operating in sectors such as heavy industry, agricultural machinery, water pumping systems, heating ventilation, and conveyor lines, many businesses in Erzurum demand motors that can perform under constant load and harsh environmental conditions. DRG Motor addresses this demand by offering IE3, IE4, and IE5 class electric motors designed for high efficiency, long life, and excellent mechanical robustness.

DRG Motor’s local sales strategy in Erzurum leverages its domestic production base and well-developed logistics network, ensuring fast delivery, technical support, and easy access to spare parts. Through local inventory and distributor connections, customers in Erzurum can minimize downtime and optimize maintenance schedules, which translates into lower operational costs and higher production continuity.

Durability is a cornerstone of DRG Motor’s design philosophy. Using GG20/GG25 cast-iron housings, the motors resist shock, vibration, and the demanding environmental conditions common in Erzurum’s industrial settings — including cold climates, dust, and high humidity. Pure copper windings and high-temperature insulation enhance winding efficiency, while optimized cooling fins ensure thermal stability and peak performance under continuous operation.

Many of DRG Motor’s units supplied to Erzurum customers are designed for S1 continuous duty. This ensures stable torque delivery, minimal wear, and high reliability over long running hours. Rotor balancing is done to G 2.5 standards, and motors operate within ISO 10816 vibration limits (≤1.8 mm/s), resulting in quiet operation and reducing mechanical stress. Such a design both increases operator comfort and extends the lifespan of bearings and other mechanical components.

High-quality SKF or C&U bearings are used in DRG Motor’s designs, complemented with high-temperature grease that increases service intervals and reduces friction-related wear. The IP55 protection rating and double-lip seal architecture safeguard the motor’s internal components from dust, moisture, and particles — crucial for maintaining reliable operations in Erzurum’s challenging environment.

To further enhance reliability, DRG Motor offers optional PTC or PT100 temperature sensors for real-time thermal monitoring. This predictive maintenance capability enables early detection of overheating or wear, reducing the likelihood of unexpected failures and minimizing unplanned downtime. Operators in Erzurum benefit from planning maintenance activities proactively rather than reactively.

Energy efficiency is a critical aspect for industrial operations in Erzurum, where electricity costs can significantly impact the bottom line. DRG Motor’s IE4 and IE5 class motors reduce energy consumption while providing strong operational performance. These motors deliver long-term value by reducing heat generation, lowering maintenance needs, and extending operational life — making them a cost-effective investment.

DRG Motor also supports its customers in Erzurum with a robust after-sales service network. Thanks to its status as a domestic manufacturer, spare parts are readily available, and technical teams assist with installation, operation, maintenance, and repair. This comprehensive support is especially valuable for Erzurum’s industrial facilities, where minimizing downtime is essential for productivity and profitability.

In summary, DRG Motor’s electric motor sales in Erzurum provide the region’s industrial and agricultural enterprises with high-performance, energy-efficient, and long-lasting motor solutions. With strong mechanical design, advanced insulation and cooling systems, reliable bearing technology, and smart thermal monitoring options, DRG Motor is a leading partner for electric motor procurement in Erzurum.

English

English

Türkçe

Türkçe