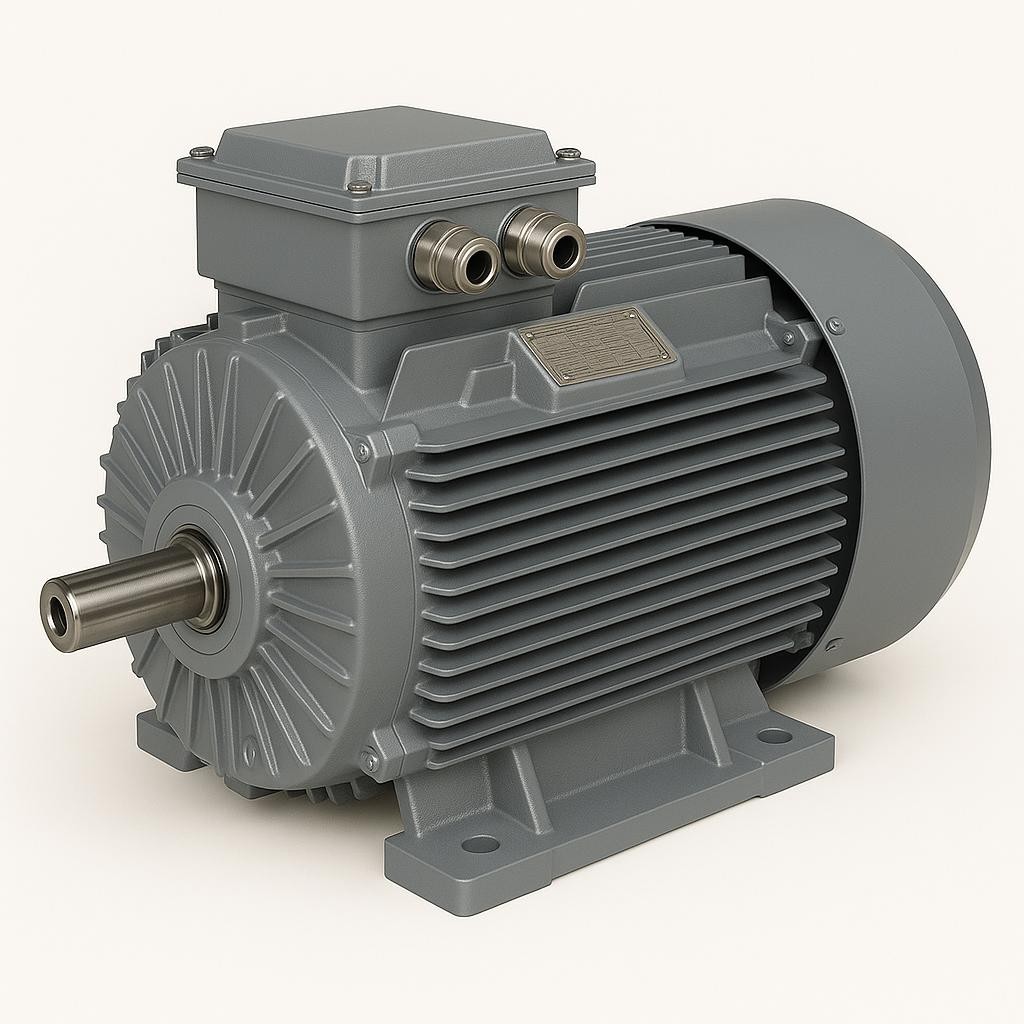

DRG MOTOR – IE3 Electric Motors

“Efficiency, Durability, and Silence Together”What is an IE3 Motor? A New Efficiency Standard in Industry

In modern industry, the cost of every kilowatt-hour directly affects operational profitability.

Electric motors account for approximately 70% of industrial energy consumption.

Therefore, motor efficiency is no longer just a technical detail; it is a strategic investment.IE3 (Premium Efficiency) motors are high-efficiency motors defined according to the IEC 60034-30-1 standard.

Compared to IE2 motors, these motors provide an average of 8–10% higher energy efficiency.As of 2024, under Türkiye’s Ecodesign Regulation,

IE3 efficiency level has become the minimum requirement for motors of 0.75 kW and above.In short:

IE3 motors consume less energy, generate less heat, have longer lifespans, and operate more quietly compared to IE2 motors of the same power.

This directly translates into reduced operational costs.

Material Quality and Construction Details of DRG MOTOR IE3 Series

Production Quality:

The DRG MOTOR IE3 series undergoes highly precise manufacturing processes.

All windings are wound on fully automated coil machines and reinforced through vacuum impregnation.Material Features:

-

100% Pure Electrolytic Copper: Reduces losses and extends winding life through high conductivity.

-

Silicon Steel (Rotor & Stator Laminations): Low core loss, high magnetic flux density.

-

Cast Iron Body (GG20): Provides high mechanical strength, impact absorption, and silent operation.

-

Bearings (SKF / C&U / NSK): High-speed durability, low friction coefficient, long life.

-

Fan and Cover Design: Optimized airflow enhances cooling efficiency while reducing noise.

Insulation System:

-

Insulation Class: F Class (155°C)

-

Operating Temperature: Max 110°C

-

Impregnation: Double-layer varnish under vacuum

-

Protection Class: IP55

Noise and Vibration Values

The DRG MOTOR IE3 series not only excels in energy efficiency but also surpasses industry standards in acoustics and mechanical balance.

Noise Levels (Sound Pressure Level – dB(A)):

Power Range Speed Noise Level Test Standard 0.75 – 7.5 kW 1500 rpm 58–62 dB(A) EN 60034-9 11 – 55 kW 1500 rpm 63–67 dB(A) EN 60034-9 75 – 200 kW 1500 rpm 68–72 dB(A) EN 60034-9 250 – 355 kW 1500 rpm 72–75 dB(A) EN 60034-9 Optimized fan profile and aerodynamic cover design reduce air turbulence, lowering noise levels.

Vibration Levels (RMS Speed – mm/s):

Test Standard Value Description ISO 10816 – N Class ≤ 1.8 mm/s Standard operation ISO 10816 – R Class ≤ 1.2 mm/s Low vibration application Each motor undergoes rotor balance testing according to G 2.5 standard after production.

This extends bearing life, prevents body resonance, and ensures quiet operation.

Thermal Design and Durability

Air channels in the motor body are designed to optimize heat dissipation.

This system:-

Distributes rotor and stator heat evenly,

-

Keeps bearing temperature below 80°C,

-

Ensures high performance during continuous operation (S1 Duty).

Mechanical Durability:

-

Body: Cast iron (GG20)

-

Shaft: C45 carbon steel

-

Covers: Cast iron

-

Paint: Industrial electrostatic powder coating (RAL 7032 / 5012 / 6028)

Thermal Protection and Insulation:

-

Insulation: F Class (155°C)

-

Thermal rise limit: <80K

Even under continuous high load, DRG MOTOR IE3 series motors maintain thermal balance, making them suitable for 24/7 operation.

Technical Specifications and Testing Processes

General Technical Specifications:

Feature Value / Description Power Range 0.55 – 355 kW Efficiency Class IE3 – Premium Efficiency Frequency 50 Hz / 60 Hz Voltage 230/400 V – 400/690 V Body Material Cast Iron Mounting Types B3, B5, B14, B35 Protection IP55 Insulation F Class Color RAL 7032 / 5012 / 6028 Certifications CE – ISO – LVD – EMC – EAC Noise 58–75 dB(A) Vibration ≤1.8 mm/s (ISO 10816) Quality Tests (Post-Production):

-

Winding resistance measurement

-

Insulation resistance test (500V Megger)

-

Rotor balance test – G2.5 standard

-

Noise test – EN 60034-9

-

Vibration analysis – ISO 10816

-

Thermal imaging control

-

Load tests (rated torque / rated current)

-

2-hour continuous operation test before delivery

Every DRG MOTOR is tested at full load on the factory test stand, and results are archived for quality assurance.

Why DRG MOTOR IE3 Series? (Advantages, Applications, and Service Life)

Energy and Cost Advantage:

IE3 motors provide up to 10% energy savings per year compared to IE2,

allowing the investment cost to be recovered within 1–2 years of operation.Quiet and Balanced Design:

All IE3 motors guarantee low noise (≤70 dB) and low vibration (≤1.8 mm/s).

Quiet operation makes a noticeable difference in pumps, fans, conveyors, and compressors.Long Service Life:

-

Bearing life: 30,000–40,000 hours

-

Body lifespan: >20 years

-

Thermal insulation lifespan: over 15 years

Applications:

Stone crushing & screening plants

Compressor and fan systems

Geared drive systems

Pump stations

Conveyor lines

Mixers and agitators

Hydraulic pressesAfter-Sales and Service:

DRG MOTOR provides nationwide service and spare parts support in Türkiye.

All products come with a 2-year warranty.

Conclusion: Silent Power, Long Life, Maximum Efficiency

The DRG MOTOR IE3 Series

is the most reliable solution for industrial facilities with low energy consumption, optimized noise and vibration levels, durable body construction, and high torque output.“Efficiency at every revolution, quality in every watt.”

DRG MOTOR – Power that works smart, quietly, and reliably.

-

English

English

Türkçe

Türkçe