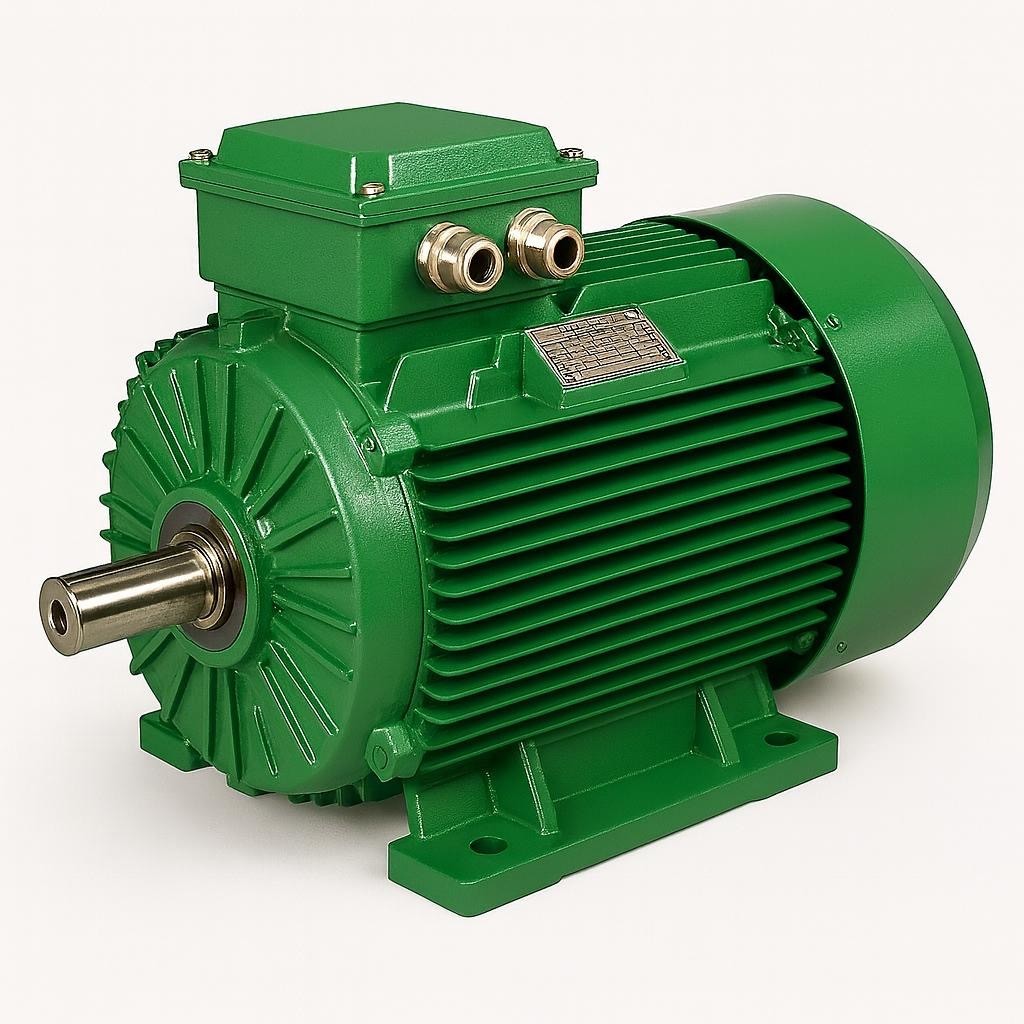

DRG MOTOR – IE5 Electric Motors

“Ultra Premium Efficiency. Silent, Powerful, Future-Ready.”

What is an IE5 Motor? Exceptional Energy Efficiency

In industrial systems, every kilowatt of energy is now a cost factor.

IE5 class electric motors represent the “Ultra Premium Efficiency” level according to the IEC 60034-30-1 standard and are currently the highest energy efficiency class in the world.

IE5 motors offer:

-

8–9% higher energy efficiency compared to IE3 motors,

-

3–4% higher energy efficiency compared to IE4 motors.

This means less energy consumption, lower carbon emissions, and reduced operating costs at the same production capacity.

The DRG MOTOR IE5 series delivers tomorrow’s energy standard today:

high efficiency, low noise, long life, and full inverter compatibility.

DRG MOTOR IE5 Series Structure and Engineering Features

High-Tech Electromagnetic Design

-

Optimized stator winding geometry for maximum magnetic flux.

-

High-silicon low-loss laminated steel stack.

-

Rotor profile minimizing hysteresis and eddy current losses.

-

High-efficiency magnetic circuit for high torque / low current balance.

Material Quality:

| Component | Feature |

|---|---|

| Windings | 100% pure electrolytic copper – vacuum impregnated |

| Body | Cast iron (GG20) – high vibration damping capacity |

| Rotor | Low-loss aluminum or copper cage rotor |

| Bearings | SKF / NSK / C&U – high-temperature grease, silent and long-lasting |

| Fan | Aerodynamic composite fan – silent cooling |

| Covers | Cast iron – high mechanical strength |

| Paint | Electrostatic powder coating – RAL 7032, RAL 6028, RAL 5012 |

Protection and Durability

-

Protection class: IP55 / optional IP65

-

Insulation class: F Class (155°C)

-

Operation type: S1 (continuous)

Noise, Vibration, and Thermal Stability Performance

The DRG MOTOR IE5 series excels not only in energy efficiency but also in acoustic and mechanical comfort.

High balance precision (G 2.5 standard) and optimized fan design ensure extremely silent and vibration-free operation.

🔊 Noise Levels (dB(A)):

| Power Range | Speed | Noise Level | Test Standard |

|---|---|---|---|

| 0.55 – 7.5 kW | 1500 rpm | 52–57 dB(A) | EN 60034-9 |

| 11 – 55 kW | 1500 rpm | 57–62 dB(A) | EN 60034-9 |

| 75 – 200 kW | 1500 rpm | 62–68 dB(A) | EN 60034-9 |

| 250 – 355 kW | 1500 rpm | 68–70 dB(A) | EN 60034-9 |

Aerodynamic fan design and the vibration-damping properties of the cast iron body keep noise levels below 70 dB(A).

Vibration Levels (mm/s – RMS):

| Test Standard | Value | Description |

|---|---|---|

| ISO 10816 / IEC 60034-14 | ≤ 1.5 mm/s | Standard operation |

| Low-vibration special production | ≤ 1.0 mm/s | For precision systems |

Thermal Structure and Cooling:

-

Maximum winding temperature: 110°C

-

Maximum bearing temperature: 80°C

-

Thermal rise: <75K

-

Optional PTC/PT100 sensor thermal protection

The DRG MOTOR IE5 series maintains stable performance even in 24/7 operation.

Energy Efficiency, Savings, and Digital Compatibility

Efficiency Gains:

| Motor Class | Efficiency Increase | Average Energy Savings |

|---|---|---|

| IE3 → IE4 | +3–5% | Up to 10% |

| IE4 → IE5 | +3–4% | Up to 15% |

| IE3 → IE5 | +8–9% | Up to 20% |

An IE5 motor saves thousands of kWh compared to an IE3 motor over 5 years, quickly offsetting its investment cost.

Digital Control and VFD Compatibility

-

Fully compatible with inverter (VFD) systems.

-

Enables speed control, energy optimization, and motor protection.

-

IoT-based monitoring allows remote tracking of temperature, vibration, and current.

“Smart motor, smart operation.”

The DRG MOTOR IE5 series integrates seamlessly into Industry 4.0-ready smart factories.

Technical Specifications and Testing Processes

Feature Value / Description Power Range 0.55 – 355 kW Efficiency Class IE5 – Ultra Premium Efficiency Voltage 230/400V – 400/690V Frequency 50 / 60 Hz Body Cast iron (GG20) Insulation F Class (155°C) Protection IP55 Noise 52–70 dB(A) Vibration ≤1.5 mm/s Certifications CE – ISO – EMC – LVD – EAC

| Feature | Value / Description |

|---|---|

| Power Range | 0.55 – 355 kW |

| Efficiency Class | IE5 – Ultra Premium Efficiency |

| Voltage | 230/400V – 400/690V |

| Frequency | 50 / 60 Hz |

| Body | Cast iron (GG20) |

| Insulation | F Class (155°C) |

| Protection | IP55 |

| Noise | 52–70 dB(A) |

| Vibration | ≤1.5 mm/s |

| Certifications | CE – ISO – EMC – LVD – EAC |

Production and Quality Tests:

-

Winding resistance and insulation test (500V Megger)

-

Rotor balance test (G 2.5 standard)

-

Noise test (EN 60034-9)

-

Vibration test (ISO 10816)

-

Load torque and current test

-

Thermal test (2 hours continuous operation)

-

Inverter compatibility check

-

Final inspection (thermal camera and bearing temperature measurement)

Each IE5 motor is tested at nominal load for 2 hours before delivery, and performance data is archived.

Why Choose DRG MOTOR IE5 Series?

-

Maximum Energy Efficiency

IE5 motors produce maximum power with minimum energy consumption.

Up to 20% energy savings over the long term.

-

Silent and Balanced Operation

Ultra-quiet operation (<70 dB(A)) and low vibration (≤1.5 mm/s).

Balance standard: G 2.5.

-

Long-Lasting Construction

Bearing life: 40,000 hours

Body life: over 20 years

Vacuum-impregnated windings resist moisture and heat.

-

Industry 4.0 Ready Design

Smart control, sensor integration, and inverter compatibility for digital production systems.

-

DRG MOTOR Assurance

-

Power range: 0.55–355 kW

-

Stock-ready options

-

2-year warranty

-

Nationwide service and spare parts support

Maximum Energy Efficiency

IE5 motors produce maximum power with minimum energy consumption.

Up to 20% energy savings over the long term.

Silent and Balanced Operation

Ultra-quiet operation (<70 dB(A)) and low vibration (≤1.5 mm/s).

Balance standard: G 2.5.

Long-Lasting Construction

Bearing life: 40,000 hours

Body life: over 20 years

Vacuum-impregnated windings resist moisture and heat.

Industry 4.0 Ready Design

Smart control, sensor integration, and inverter compatibility for digital production systems.

DRG MOTOR Assurance

Power range: 0.55–355 kW

Stock-ready options

2-year warranty

Nationwide service and spare parts support

Conclusion: The Pinnacle of Efficiency – DRG MOTOR IE5 Series

The DRG MOTOR IE5 Series

introduces a new era in industrial systems with energy efficiency, silence, torque stability, and long-lasting engineering.

“Less energy, more performance.”

DRG MOTOR – Ultra Premium Efficiency. Super Silent. Future Ready.

English

English

Türkçe

Türkçe