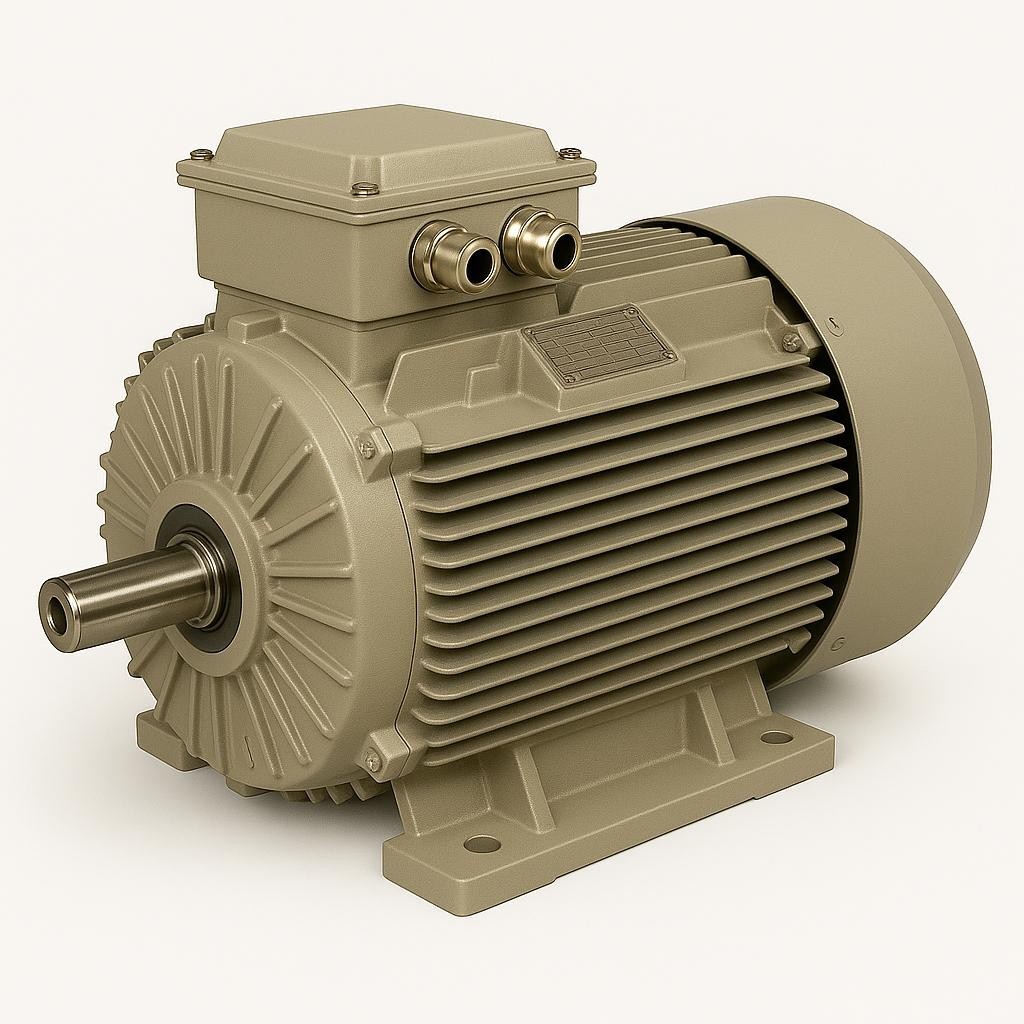

DRG MOTOR – STONE CRUSHING PLANT ELECTRIC MOTORS

“Uninterrupted Power Even Under the Toughest Conditions.”

Importance of Motors in Stone Crushing Plants

Stone crushing and screening plants are among the systems exposed to the highest mechanical stress in heavy industry.

The motors used in these facilities must withstand:

-

High starting torque,

-

Sudden load variations,

-

Intense dust and vibration,

-

Continuous 24/7 operation.

The DRG MOTOR Stone Crushing Series is specially designed for these demanding conditions, featuring high torque, heat resistance, dustproof protection, and vibration-damping construction.

Each motor is optimized for equipment such as crushers, screens, conveyors, and bunkers.

“Strong against stone, resistant to dust, ready for continuous duty – DRG MOTOR.”

Structural Features of the DRG MOTOR Stone Crushing Series

Material and Design Features:

Body: Cast iron (GG20) – high vibration resistance and long service life.

Windings: 100% pure electrolytic copper, vacuum impregnated for superior insulation.

Rotor: Squirrel-cage rotor – high balance and torque transmission.

Fan: Heat-resistant composite fan – dust-protected airflow.

Bearings: SKF / C&U high-temperature grease bearings – suitable for heavy-duty conditions.

Covers: Reinforced cast iron covers – impact-absorbing structure.

Paint: Chemically resistant electrostatic powder coating (RAL 7032 / 6028 / 5012).

Technical Specifications:

Feature Value / Description Power Range 0.55 kW – 355 kW Voltage 400 / 690V Frequency 50 / 60 Hz Speed Options 750 / 1000 / 1500 rpm Body Cast Iron Insulation F Class (155°C) Protection IP55 Mounting B3, B35, B5

| Feature | Value / Description |

|---|---|

| Power Range | 0.55 kW – 355 kW |

| Voltage | 400 / 690V |

| Frequency | 50 / 60 Hz |

| Speed Options | 750 / 1000 / 1500 rpm |

| Body | Cast Iron |

| Insulation | F Class (155°C) |

| Protection | IP55 |

| Mounting | B3, B35, B5 |

The DRG MOTOR Stone Crushing Series is manufactured in S1 continuous duty class for heavy industrial operation.

High Torque, Low Vibration, Long Service Life

Stone crushing plants expose motors to severe mechanical impacts and high starting loads.

For this reason, DRG MOTOR has developed a special series of high-torque and vibration-resistant motors for crushing systems.

High Starting Torque:

-

Rotor design optimized for high moment at startup.

-

Ensures easy starting of loaded crushers, bunkers, or conveyor systems.

-

Low current draw and high durability under frequent start-stop operations.

Vibration Resistance:

-

Thick cast iron structure prevents body resonance.

-

Dynamic rotor balancing according to G 2.5 standard.

-

Bearing housings with additional shock-absorbing design.

Long-Life Continuous Operation:

-

Designed for full-load 24/7 operation.

-

Maximum temperature rise: <75K

-

Maximum winding temperature: 110°C

“Crushers never stop – DRG MOTOR provides the power behind them.”

Noise, Vibration and Thermal Performance

🔊 Noise Levels (dB(A)):

| Power Range | Speed | Noise Level | Test Standard |

|---|---|---|---|

| 5.5 – 22 kW | 1500 rpm | 63–68 dB(A) | EN 60034-9 |

| 30 – 110 kW | 1500 rpm | 68–72 dB(A) | EN 60034-9 |

| 132 – 355 kW | 1500 rpm | 72–75 dB(A) | EN 60034-9 |

Vibration Levels (mm/s – RMS):

| Test Standard | Value | Description |

|---|---|---|

| ISO 10816 | ≤ 1.8 mm/s | Normal operation |

| ISO 10816 (special balance) | ≤ 1.2 mm/s | For low-vibration geared systems |

Thermal Structure:

-

Bearing temperature: max. 80°C

-

Winding temperature: max. 110°C

-

Thermal rise: <75K

-

Motor body features heat-dissipating fins for cooler continuous operation.

Dusty Environment and Protection Features

Stone crushing plants are exposed to high levels of dust, moisture, and vibration.

Therefore, the protection class of the motor is one of the most critical factors determining its lifetime.

Protection Features:

-

IP55: Strong protection against dust and water ingress.

-

Double-lip bearing seals: Prevent dust and mud penetration.

-

Fan cover: Reinforced metal grid-protected structure.

-

Paint coating: Chemical-resistant, long-lasting powder finish.

Testing Procedures:

-

Insulation and winding test (500V Megger).

-

Rotor balance test (G 2.5 standard).

-

Noise test (EN 60034-9).

-

Vibration analysis (ISO 10816).

-

Thermal load test (2 hours under nominal load).

-

IP tests (dust, moisture, and water tightness).

DRG MOTOR runs every motor under full load at the testing station before shipment to ensure perfect quality control.

Application Areas and DRG MOTOR Advantages

Application Areas:

-

Mobile and stationary crusher plants

-

Screen motors

-

Feeding bunkers

-

Conveyor belt systems

-

Geared drive systems

-

Dust collection fan motors

-

Washing and pump units

Advantages of the DRG MOTOR Stone Crushing Series:

-

High Starting Torque – Easily starts heavy loads.

-

Cast Iron Body Durability – Long service life against impacts and vibration.

-

Thermal Stability for S1 continuous duty operation.

-

Quiet and Balanced Rotor Design (G 2.5).

-

Long Bearing Life – Over 40,000 hours.

-

High Efficiency – Available in IE3, IE4, IE5 classes.

-

Ready Stock – From 0.55 kW to 355 kW.

-

2-Year Warranty and Nationwide Service Support.

“The DRG MOTOR Stone Crushing Series is the power that never stops, even in the harshest environments.”

The Heart of Heavy Industry – DRG MOTOR

DRG MOTOR Stone Crushing Plant Motors deliver high torque, dust protection, quiet operation, and exceptional durability, making them the most reliable power source for heavy industrial operations.

“Dust, vibration, load – it doesn’t matter. DRG MOTOR works under any condition.”

DRG MOTOR – The Power of Heavy Industry.

English

English

Türkçe

Türkçe