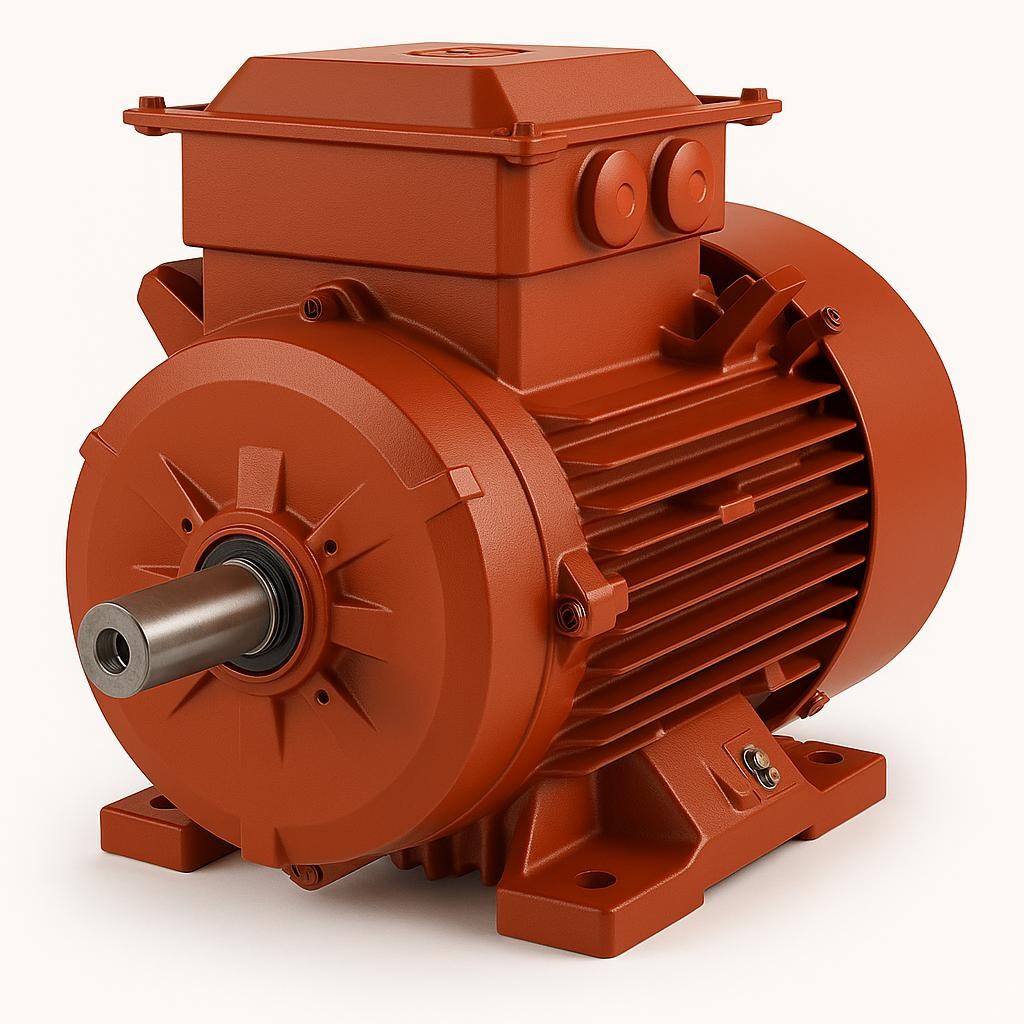

DRG MOTOR 45 kW 1000 RPM NEW GENERATION ELECTRIC MOTOR

Contact: +90 (542) 666 11 11

The Drg Motor 45 kW 1000 RPM New Generation Electric Motor is a high-performance industrial solution designed for modern manufacturing facilities that require reliability, durability, and efficiency. Optimized for heavy-duty applications and continuous operation, this motor ensures maximum performance in conveyors, pumps, fan systems, mixers, stone crushing and screening plants, and industrial presses.

Structural and Material Features

The motor’s cast-iron (GG20) body provides exceptional durability and vibration damping, protecting the motor against mechanical shocks and industrial vibrations. Aerodynamically optimized fan blades and internal air channels ensure maximum heat dissipation, keeping the motor cool even during extended operation.

Windings are made of 100% pure electrolytic copper and vacuum-impregnated for minimal energy loss, complying with IE3/IE4 efficiency standards. The rotor is a high-precision cage type, ensuring low vibration and effective torque transmission. SKF / C&U bearings are greased for high-temperature operation and long service life.

The motor’s IP55 protection ensures safe operation in dusty, humid, and harsh environments. Dual lip bearing seals increase durability in demanding industrial conditions. The fan housing features reinforced metal grids, and the electrostatic powder coating provides chemical and mechanical resistance.

Performance and Efficiency

With 45 kW power and high starting torque, the motor easily initiates heavy loads, critical for crushers, gear-driven conveyors, bunkers, and pumps. Its low current draw optimizes energy consumption and ensures durability under start-stop cycles.

The motor complies with IE3 and IE4 energy efficiency classes, reducing operational costs and energy consumption. Low vibration and quiet operation extend bearing life and reduce maintenance. IEC-standard B3, B5, and B35 mounting options allow easy system integration.

Noise, Vibration, and Thermal Features

The motor operates at 63–75 dB(A) noise levels, tested according to EN 60034-9 standards. Vibration levels are ≤1.8 mm/s (ISO 10816) and ≤1.2 mm/s for special balanced versions. Maximum winding temperature is 110°C, bearing temperature is 80°C, with thermal rise <75K. Optional PTC/PT100 sensors allow thermal monitoring.

Testing and Quality Assurance

The Drg Motor 45 kW undergoes rigorous testing:

-

Winding and insulation resistance tests (500V Megger)

-

Rotor balance testing (G 2.5 standard)

-

Noise and vibration measurements (EN 60034-9, ISO 10816)

-

Thermal load testing and continuous operation (S1 Duty – 2 hours)

-

IP55 protection testing (dust, water, humidity)

-

Load-based current and torque analysis

These tests ensure reliability and long-lasting performance.

Applications

-

Conveyor belts and gear-driven systems

-

Water and chemical pumps

-

Fan and ventilation systems

-

Mixers, industrial presses, and crushers

-

Stone crushing and screening plants

-

Agricultural and construction machinery

DRG MOTOR Advantages

-

High efficiency and energy savings (IE3/IE4)

-

Low noise and vibration

-

Long-life bearings and windings

-

Cast-iron body resistant to shocks and vibrations

-

IP55 protection for dust and moisture

-

IEC-standard mounting options

-

24/7 operation capability

-

2-year warranty and nationwide technical support

About DRG Motor

DRG Motor is a leading brand providing industrial electric motors combining high efficiency, long service life, and durability. All motors are designed and manufactured to meet the toughest industrial conditions and modern energy efficiency standards.

English

English

Türkçe

Türkçe