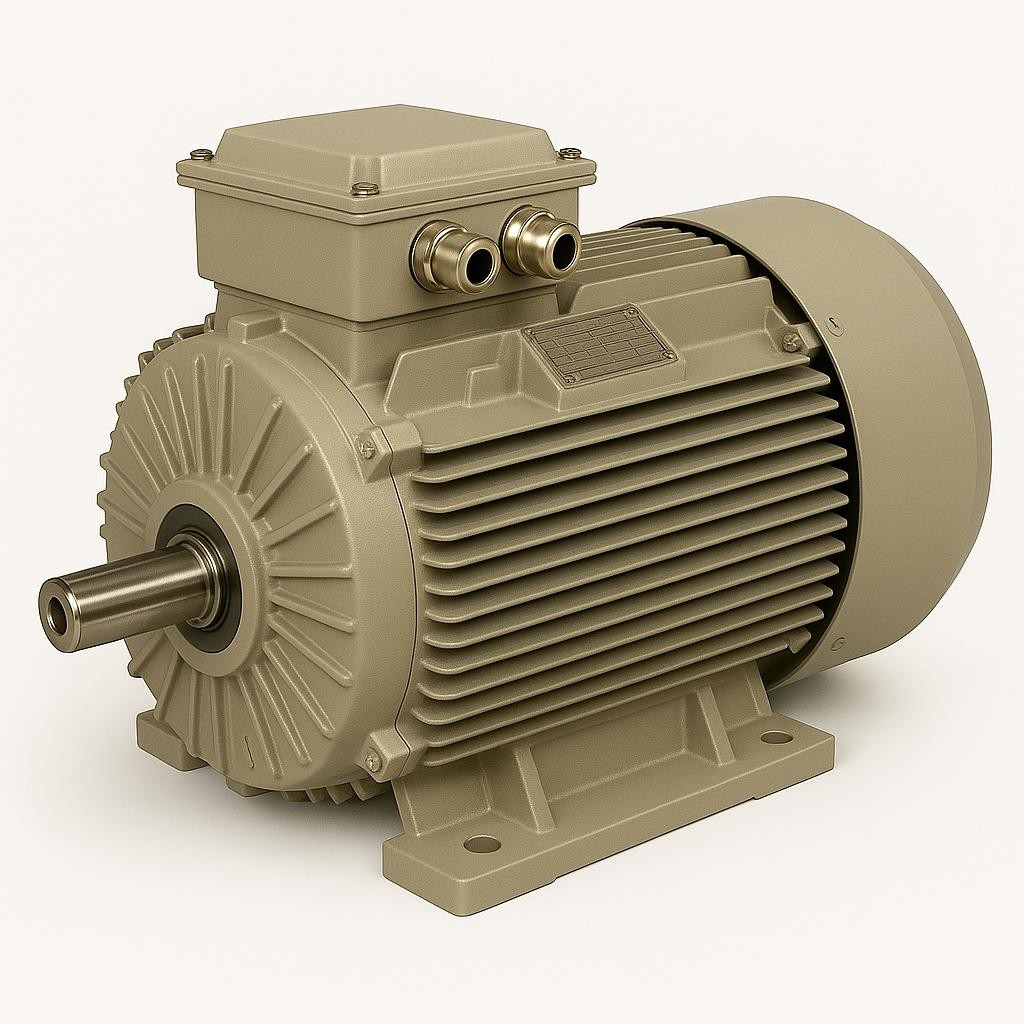

DRG MOTOR 355 kW 1500 RPM NEXT-GENERATION ELECTRIC MOTORS

Contact: +90 (542) 666 11 11

The Drg Motor 355 kW 1500 RPM Next-Generation Electric Motors are engineered to deliver maximum performance, long service life, and superior energy efficiency in high-demand industrial operations. These motors are ideal for heavy-duty conveyor lines, crushing and screening plants, high-capacity pumps, industrial mixers, and geared drive systems, operating under extreme mechanical and thermal loads.

The robust housing is made from cast iron (GG20/GG25), providing excellent resistance against impact and vibration. Optimized cooling fins on the motor casing ensure minimal temperature rise even during continuous operation, enhancing efficiency. The rotor cage structure is made of specially alloyed bars to provide high torque while maintaining low vibration. The windings are made from 100% pure electrolytic copper, vacuum impregnated for long-term resistance against high temperatures and moisture.

This 355 kW motor is available in IE3, IE4, and IE5 efficiency classes, allowing industrial facilities to reduce energy costs and comply with sustainable industrial standards. High torque capacity, low-speed design, and balanced rotor structure ensure stable and safe operation under sudden load changes and start-stop cycles.

Bearings are SKF / C&U, lubricated with high-temperature grease, and double-lip seals provide protection against dust, mud, and moisture. With an IP55 protection rating, the motor can operate reliably in dusty and humid environments. Advanced thermal features maintain the maximum winding temperature at 110°C and maximum bearing temperature at 80°C. Optional PTC or PT100 sensors can be integrated for precise temperature monitoring.

The DRG Motor 355 kW 1500 RPM series undergoes rigorous pre-shipment testing, including load performance tests, insulation resistance tests, rotor balancing, noise and vibration analysis, continuous operation (S1 Duty) tests, IP55 environmental resistance tests, and energy efficiency evaluations. Motors that pass these tests are ready for long-term reliable operation in industrial facilities.

Applications:

-

Crushing and screening plants

-

High-capacity conveyor systems

-

Large industrial pumps

-

Industrial mixers

-

Geared drive mechanisms

-

Mining operations

-

Cement and chemical plants

Advantages of DRG Motor:

-

High torque with low-speed operation

-

IE3 / IE4 / IE5 energy efficiency classes

-

24/7 continuous duty operation

-

Low vibration and quiet operation

-

High thermal resistance

-

Durable cast iron housing and optimized rotor design

-

Minimal maintenance and long bearing life

-

B3 / B5 / B35 mounting options

-

Nationwide service and spare parts support

About DRG Motor:

DRG Motor is a leading engineering brand in industrial electric motors, combining high performance, durability, and energy efficiency. All products are manufactured according to international quality standards and are designed to operate reliably in heavy-duty industrial conditions for years.

English

English

Türkçe

Türkçe