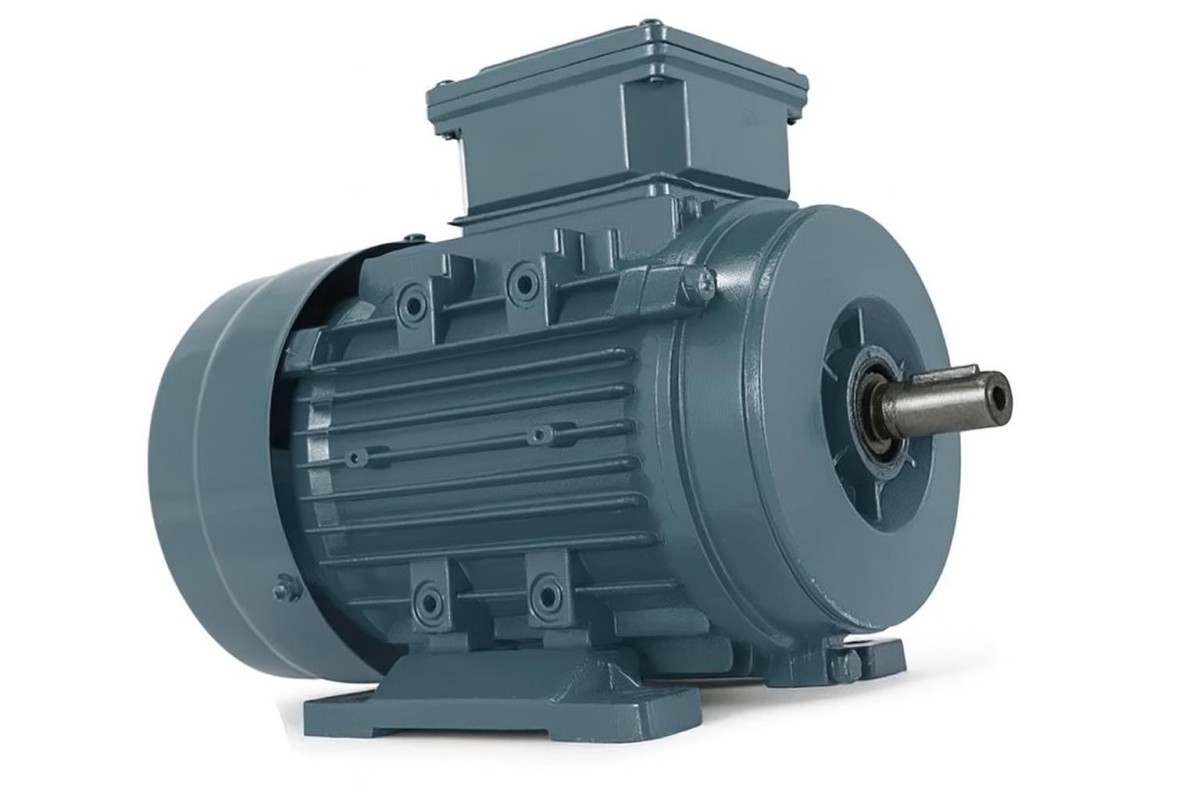

DRG MOTOR 132 kW 1000 RPM NEW GENERATION ELECTRIC MOTOR

Contact: +90 (542) 666 11 11

The Drg Motor 132 kW 1000 RPM New Generation Electric Motor combines high power capacity and industrial durability, delivering reliable performance in heavy-duty industrial applications. It ensures the safe operation of pumps, conveyor lines, fans, mixers, and various industrial machinery. With a nominal speed of 1000 RPM and high starting torque, it guarantees smooth operation even under heavy loads.

Structural and Material Features

The motor body is made of cast iron (GG20), providing vibration damping and shock resistance. Aerodynamic fan design and optimized internal channels maintain low operating temperature during continuous operation.

Windings are 100% pure electrolytic copper, vacuum impregnated, and compliant with IE3 / IE4 efficiency standards. The rotor is cage-type, delivering low vibration and high torque transfer. Bearings are SKF / C&U, greased for high temperature, and long-lasting.

The motor is IP55 rated for dust and water protection. Dual lip bearing seals and reinforced fan housing enhance motor durability. The powder-coated body resists chemical and mechanical impact.

Performance and Efficiency

The 132 kW motor delivers high starting torque for heavy loads, making it ideal for crushers, gear-driven conveyors, bunkers, and pumps. Low current draw increases energy efficiency and ensures compliance with IE3 / IE4 standards.

Low vibration and quiet operation extend bearing life and reduce maintenance. IEC-standard B3, B5, and B35 mounting options allow easy integration.

Noise, Vibration, and Thermal Features

-

Noise level: 72–76 dB(A), tested according to EN 60034-9

-

Vibration: ≤1.8 mm/s (ISO 10816), ≤1.2 mm/s for special balanced versions

-

Maximum winding temperature: 110°C

-

Maximum bearing temperature: 80°C

-

Thermal rise: <75K

-

Optional PTC/PT100 sensors available

Testing and Quality Assurance

Before leaving the production line, each motor undergoes:

-

Winding and insulation resistance testing (500V Megger)

-

Rotor balance testing (G 2.5 standard)

-

Noise and vibration measurements (EN 60034-9, ISO 10816)

-

Thermal load and continuous operation testing (S1 Duty – 2 hours)

-

IP55 protection tests

-

Load-based current and torque analysis

Applications

-

Conveyor belts and gear-driven systems

-

Water and chemical pumps

-

Fan and ventilation systems

-

Mixers and industrial presses

-

Stone crushing and screening plants

-

Agricultural and construction machinery

DRG MOTOR Advantages

-

High efficiency and energy savings (IE3/IE4)

-

Low noise and vibration

-

Long-lasting bearings and windings

-

Cast iron body resistant to shocks and vibrations

-

IP55 protection against dust and moisture

-

IEC-standard mounting options

-

24/7 operation

-

2-year warranty and nationwide technical support

About DRG Motor

DRG Motor is a leading brand in industrial electric motors, combining high efficiency, durability, and long service life. All motors are designed and manufactured to meet heavy industrial conditions and modern energy efficiency standards.

English

English

Türkçe

Türkçe