Alternating Current Electric Motor Prices

Contact: +90 (542) 666 11 11

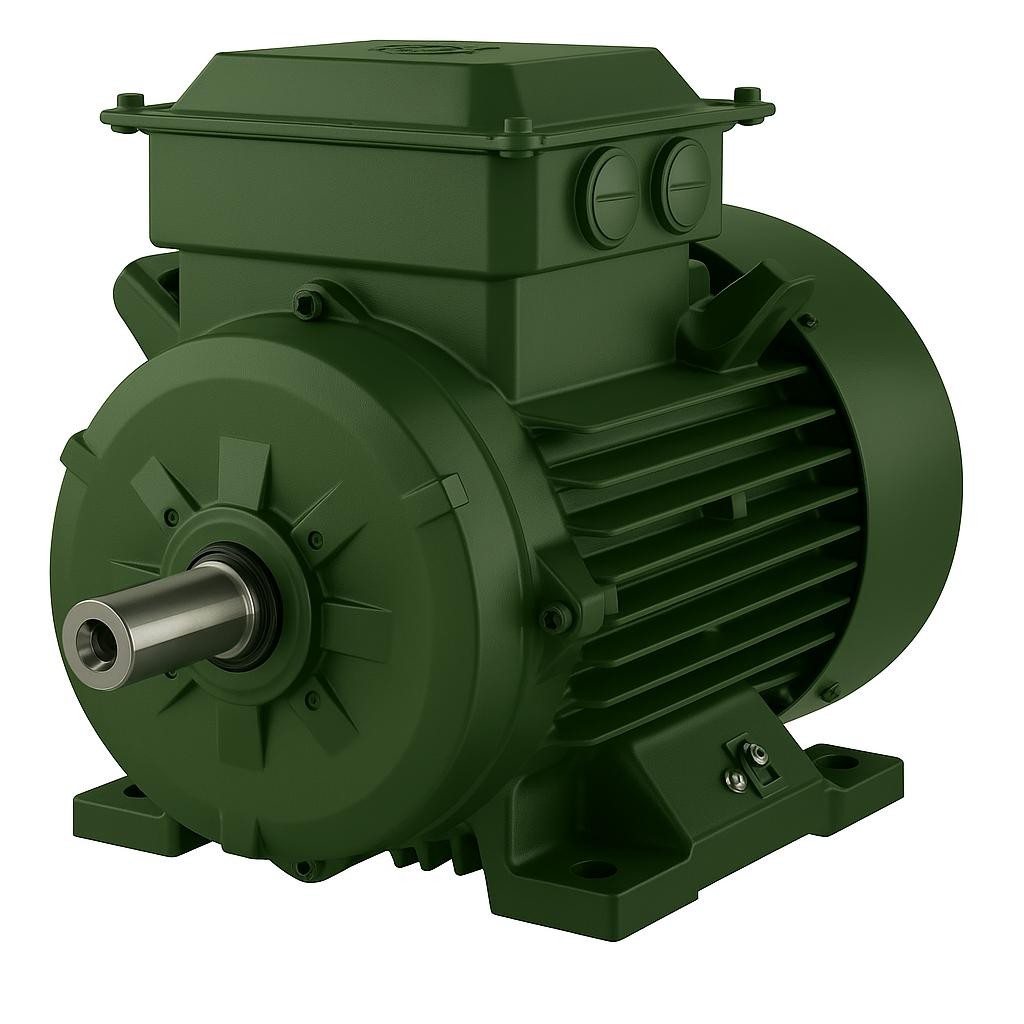

Alternating current (AC) electric motor prices are an important consideration for industrial and commercial businesses when selecting the right motor to meet their power transmission and energy efficiency needs. AC electric motors are widely used in many industrial and commercial applications—including pump systems, fans, compressors, and conveyor belts—due to their broad range of applications, durability, and high performance. Therefore, the term “Alternating Current Electric Motor Prices” represents not only a cost search, but also factors such as long-term performance, low operating expenses, and sustainable use.

The key factors that influence AC motor prices include motor power (kW/HP), efficiency class (especially IE2, IE3 and above), rotational speed (RPM), frame type, insulation class, and special technical specifications according to the application. In addition, brand, stock availability, delivery time, and after-sales services can also affect pricing. Businesses consider both an appropriate cost and long-term energy savings when selecting the motor that meets their needs.

High-efficiency AC electric motors provide economic advantages, especially in continuously operating applications, by significantly reducing energy costs. This advantage helps balance the initial investment cost and achieve a quicker return on investment and is an important choice for companies aiming to comply with energy efficiency regulations.

Technical support and after-sales services play a major role in AC electric motor investments. Getting expert assistance in motor selection, pre-installation consultancy, maintenance, and troubleshooting provides advantages in system performance, reliability, and durability. With professional support, businesses can make the most suitable motor selection in terms of both performance and price.

In conclusion, when evaluating alternating current electric motor prices, businesses should consider not only cost, but also factors such as efficiency, performance, and long-term savings. With the right product selection and professional technical support, companies can achieve maximum efficiency and minimum cost in their production processes.

English

English

Türkçe

Türkçe