Adana Electric Motor Price List

Contact: +90 (542) 666 11 11

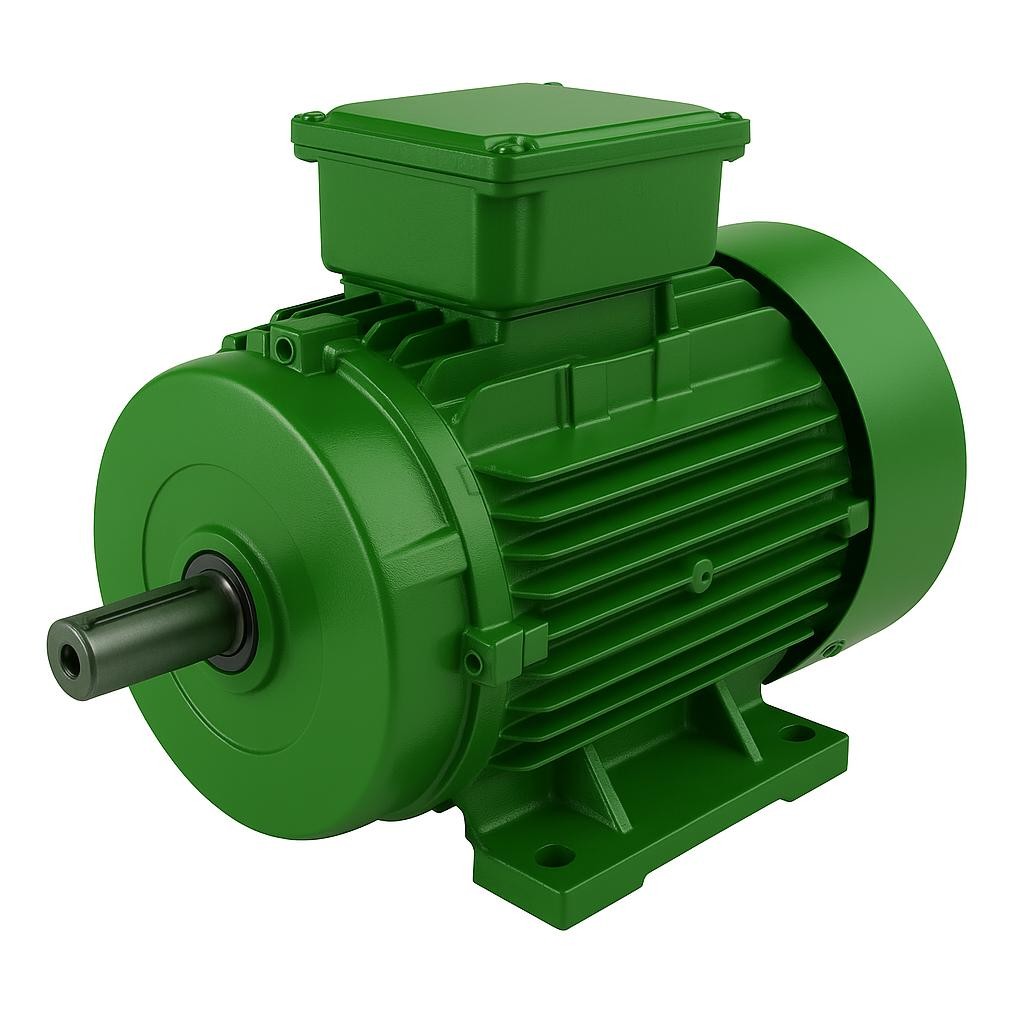

Adana is one of Turkey’s prominent industrial cities, with significant demand for electric motors in sectors such as agricultural machinery, irrigation systems, fans, pump lines, and manufacturing. In this market, DRG Motor stands out as a key provider, offering efficient, durable, and long-lifespan electric motor solutions tailored to the needs of Adana-based businesses.

1. Product Range and Efficiency Classes

DRG Motor offers IE3, IE4, and IE5 efficiency class motors for its Adana customers. These motors can be configured for various power (kW) and speed (RPM) requirements. IE4 and IE5 high-efficiency models significantly reduce energy consumption, delivering long-term savings in operational costs—a crucial advantage in energy-intensive industrial environments found in Adana.

2. Structural Durability and Housing Material

The motors feature GG20 / GG25 cast-iron housings designed for robustness against impact, vibration, and harsh industrial conditions. This sturdy construction ensures mechanical stability even in hot and demanding environments. In the open-air industrial zones common in Adana, this resilience is a major asset.

3. Winding, Insulation, and Cooling

DRG Motor uses pure copper stator windings combined with high-temperature insulation to optimize thermal performance and minimize overheating risk. In addition, carefully designed cooling fins distribute operating heat evenly during usage, maintaining efficiency and performance stability.

4. Continuous Operation, Rotor Balance, and Vibration

The Adana-specific motor models from DRG are typically engineered for S1 continuous duty, allowing for stable torque delivery during long operation cycles. Rotor balancing adheres to the G 2.5 standard, while vibration levels remain at or below ISO 10816 ≤ 1.8 mm/s, minimizing wear and mechanical stress.

5. Bearing Technology

High-quality SKF or C&U bearings are used in DRG motors, lubricated with high-temperature grease. This choice extends bearing life, lowers frictional wear, and enables longer maintenance intervals—critical factors in reducing total operational cost, especially in industrial applications.

6. Protection and Sealing

DRG motors come standard with IP55 protection class and a double-lip seal system. These features protect internal components from dust, moisture, and particles—essential for reliable performance in industrial settings with limited maintenance windows.

7. Sensor & Monitoring Capabilities

Optional PTC or PT100 temperature sensors can be integrated into the motor for real-time thermal monitoring. This predictive capability allows early detection of overheating or failure, helping businesses in Adana plan maintenance proactively and reduce unplanned downtime.

8. Energy Savings and Operating Costs

IE4 and IE5 class motors significantly reduce energy consumption, helping businesses cut down on electricity expenses. Moreover, the combination of low vibration, optimized winding structure, and long-life bearings reduces maintenance costs, making DRG motors a cost-effective and sustainable choice for industrial operations.

9. Logistics & Service Benefits

As a local manufacturer, DRG Motor offers logistical advantages in Adana—fast delivery, technical support, and spare part availability are more accessible. Their service team provides professional assistance for installation, commissioning, regular maintenance, and troubleshooting, helping businesses minimize downtime.

10. Conclusion & Competitive Advantage

For industrial and commercial enterprises in Adana, DRG Motor’s electric motors provide key benefits: robust construction, high efficiency, long lifespan, and low maintenance costs, combined with the advantages of local production. In the IE3–IE5 motor classes, DRG Motor offers a reliable, performance-driven, and economically sustainable solution for Adana’s dynamic industrial sector.

English

English

Türkçe

Türkçe